Wednesday, December 23, 2015

Friday, November 13, 2015

Friday Feature: Ben & Mitch

This summer, Klocke Farms and PigEasy were fortunate to add

a couple members to the team. Their involvement with PigEasy varies, but as

with everyone else in our operation, they are a part of just about everything.

Welcome to PigEasy and Klocke Farms, Ben and Mitch!

|

| Ben Klocke and Mitch Tiefenthaler began working for Klocke Farms and PigEasy this summer. |

Ben

No, this is not my brother Ben that I’m talking about here,

and yes, there have been some confusing moments.

Ben Klocke (the other Ben Klocke in Carroll County!) started

working with Klocke Farms in July.

We knew early on that one of the Bens would

need a nickname. After much deliberation, Ben Klocke (new Ben Klocke) accepted

the nickname of “FJ”. Can anyone guess what “FJ” stands for? Let’s have an

informal contest; the first one who figures it out and comments below gets a

free t-shirt! (Karen says keep it clean!)

Ben’s main focus is Klocke Farms’ day to day tasks, but does

help with PigEasy production.

Mitch

Mitch joined the team in August and hit the ground running getting

up to speed with PigEasy operations and products in addition to taking part

in Klocke Farms. While Mitch has spent a

lot of his first few months in a tractor helping with harvest, he has taken on

the role of PigEasy inventory, order management and shipping.

Post-harvest, Mitch’s

main focus will be PigEasy; we look forward to streamlining our system with

Mitch’s help!

Now that we are finished with harvest, we often look back

and wonder how the heck we did it all without these guys.

Have a great weekend,

Katie

Monday, October 5, 2015

Pigs per Sow Lifetime

What is it and why is it so important?

|

| MealMeter feed dispenser |

When we set out to develop the MealMeter, we were focused on two main benefits; to increase production while decreasing feed waste. Now that

we have had the MealMeter in front of pre breed gilts, weaned and under

conditioned sows, and lactating sows for a few years on our sow farm, we are

noticing many side benefits that are just as important, which are increased pigs per sow lifetime and reduced early culling.

Let’s focus on pigs per sow lifetime. In a recent NationalHog Farmer article, Ron Ketchum and Mark Rix from Swine Management Services

explained this calculation as (pigs

weaned lifetime from females culled, died and euthanized) divided by (females

culled plus females died plus females euthanized).

This is an important number, arguably more important than

PSY, because it is a better look at the overall ROI of each sow. A sow as an

economic unit does not reach profitability until after parity three. Also, pigs

from multi-parity sows have higher wean weights and perform better in the grow/finish sector.

Pork Network published an article a month ago called “How the U.S. pork industry can make an additional $250 million” that discusses

the benefits of focusing on sow longevity.

“If each sow in the U.S. produced one more litter in her

lifetime, the U.S. swine industry would generate another $250 million of net

value for the pork industry,” says Jon Bergstrom, Ph.D., senior technical

support manager for DSM Nutritional Products.

So what does this have to do with the MealMeter?

By ad lib feeding at critical times in a sow’s reproductive

cycle, over time we have been able to greatly increase our pigs per sow

lifetime, reduce early culling, and therefore reduce our replacement rate

in addition to many other benefits.

The image below displays those critical times in

orange. When pre breed gilts and sows

are able to efficiently consume their rations to maintain condition, they will

in turn perform better in subsequent parities and remain in the herd much

longer.

It’s time to put my money where my mouth is.

When developing the MealMeter, we noticed that gilts would

adapt quickly and limited intake days were avoided. This turned into higher P1

performance, which then led us to putting it in front of the weaned and under

conditioned sows, along with lactating sows. These immediate benefits were

apparent, along with better feed efficiency and less feed waste.

Over the long term, we began to see much less fallout from

our herd. Sows who started off on the MealMeter continued to perform well and

we were able to reduce involuntary culling of younger, low parity sows with

performance issues from lack of consistent feed intake.

Overall, using the MealMeter has made a lasting impact in

our operation.

But let’s talk numbers.

The year before implementing the MealMeter, our farm’s average pigs

per sow lifetime was 45, which was a pretty reasonable number to us at the time.

So far in 2015, our average pigs per sow lifetime has shot up to 58 and we are

seeing the numbers continue to trend upward.

The return on investment is far reaching as higher lifetime production

mean our sows are staying in the herd longer. This increases profitability

while producing heavier, healthier pigs.

(10/12/2015) http://www.pigprogress.net/Breeding/General/2015/9/Predicting-sow-reproductive-performance-after-parity-1-2680854W/

Until next time,

Katie

For more information on the MealMeter, you can visit the PigEasy website, www.pigeasy.com.

If you’d like to talk to us about its benefits on our sow farm and how we can help you get started with the MealMeter, please call 888-354-0112.

Tuesday, July 28, 2015

The "Special Sauce" to Feeding in Lactation

|

| PigEasy Feeder Set Up |

Veterinarians, nutritionists and consultants have been promoting ad lib feeding sows in lactation for years due to its many short and long term benefits. Overall, ad lib feeding removes the human element of feed intake, thus giving each sow the ability to choose how much feed she wants to consume throughout the day while greatly cutting down on feed waste.

Common concerns we hear from producers are “Well, we use Brand

X of ad lib feeders and all she does is play with it” or “Even though Brand Y

Feeder has increased feed consumption, you’ll still see a layer of feed at the

bottom of the trough that can build up if staff doesn’t clean it out in the

morning.” Basically, feed build up continues to be an issue with certain sows,

which will either eat up your time cleaning out feeders or will inhibit future

consumption if the feed becomes stale or rotten.

To combat this, the industry developed certain ad lib

feeders to be wet/dry, but they came with their own set of issues. Producers

have commented on a lot of plugging problems with messes or a bowl full of

water from a leaky nipple or the sow over watering herself. Basically, they

became a mess.

So what is a producer to do?

In the past, producers chose a lesser of two evils and

simply dealt with the negatives. This is

a step in the right direction as we all know how important it is to give her as

much feed as possible in lactation.

But what if you could get each sow to the next level WITHOUT

having to clean bowl after bowl every day?

It took years of observation and a lot of trials, but Dave came

up with the right ingredients to give the sow the power to consume while at the

same time training her not to waste.

PigEasy’s not-so-secret ingredients to successful feeding is

all about the type of water bracket and nipple and its placement, cutting or

drilling a weep hole, and the type of feed bowl.

|

| PigEasy Water Bracket |

First, the water bracket needs to be a simple straight pipe

with a wet/dry nipple, although we recommend a button nipple. The PigEasy

Lactation Water Bracket is a straight stainless steel pipe with two adjustable

brackets on the back side.

|

| Adjustable Brackets |

|

| Low position of water bracket in a retrofitted lactation feeder. |

With these small changes, you give each sow the power without

dealing with the waste, and that is a huge difference. But don’t jump in

blindly; try it out and see the benefits yourself.

For any questions on how to maximize feed intake at critical

points in a sow’s reproductive cycle, call PigEasy at (888) 354-0112.

Wednesday, June 10, 2015

World Pork Expo Reflections

|

| The PigEasy Booth was located on the southwest wall of the Varied Industries Building. |

As you saw in Katie’s prior blog post, the World Pork Expo

has been a family interest for years. I

now have a different perspective on the other side of the booth.

Beyond the planning and organizing prior to, the “move in”

day becomes a group effort.

One of my favorite moments was watching this man with his

young boy work together in preparing his booth.

First the young boy was directing his Dad in parking his trailer. Then they both made trips carrying and

pulling in various items for their booth (and the young boy had such a serious

task-driven look on his face). The next

time I saw them, they were laughing and high fiving each other. Each moment brought back memories of our kids

working with us. Made my heart swell.

One of my favorite moments was watching this man with his

young boy work together in preparing his booth.

First the young boy was directing his Dad in parking his trailer. Then they both made trips carrying and

pulling in various items for their booth (and the young boy had such a serious

task-driven look on his face). The next

time I saw them, they were laughing and high fiving each other. Each moment brought back memories of our kids

working with us. Made my heart swell.

So on the other side of the booth, you realize what it takes

to be a vendor. For PigEasy, third time was a charm. With the debut of our PigEasy products, the

first couple of years the attendees were like buying a car –“kicking the tires

and looking it over”. This year, it was

exciting to talk to those that have used our products and to people with a real

intent.

|

| We couldn't do it without our leadership! |

It is great to see familiar faces and spend time with them –

vendors and attendees. The food was

excellent, the weather turned out great, and the attendance was a constant buzz

of people. I was in a mother’s dream –

all four kids were able to attend; one spouse (the other was out of state

dutifully serving our country), my brother and sister-in-law, our PigEasy Board

members and spouses, and employees.

As we pulled away from the four days of the Expo 2015, it

made me wonder – will that young son join his Dad in his business like Ben and

Katie did with us. Makes my heart swell!

- Karen

Wednesday, May 27, 2015

These Little Piggies are heading to the World Pork Expo...

The 2015 World Pork Expo is exactly one week away and we couldn't be more excited.

In our younger years, we would love to tag along with Dad to sneak treats (everyone remember the flavored slushies in the semen bags at the ZFI booth??) and eat as much barbecued pork as our stomachs would allow. Oh, and I suppose we would learn about all the new products and technologies while Dad stopped by his favorite booths to talk to old friends.

Since we morphed from attendee to exhibitor a few years ago, some of our focus has changed, but most stayed the same.

And while I do miss being able to leisurely wander through the aisles on the day we'd attend, it is a captivating experience to meet so many people in a mere three days that are as enthusiastic about pork production as we are.

This year we are featuring the redesigned MealMeter. As Dad continues to observe and innovate, he also improves our current products. The updated MealMeter nose piece design funnels the feed flow and increases durability.

In addition to the MealMeter itself, we have a freshly designed farrowing crate that is made of stainless steel where you need it and mild steel in the areas where wear isn't an issue in order to keep it reasonably priced.

The Chuck-It Bucket holding/disposal tank will be displayed at the QC Supply booth (#V489).

We have a lot to look forward to next week, barbecued pork included, and we can't wait to visit with pork producers from around the world!

- Katie

Monday, May 11, 2015

Optimizing Intake in Lactation

Many pork producers have acknowledged the importance of ad

lib feeding in lactation for a number of reasons. First and foremost, lactation puts huge caloric

demand on a sow as they are feeding larger litters. If we are not giving her access to full feed,

there is a chance she will lose condition, which will raise the likelihood of

that sow being culled exponentially as she turns from a productive sow to an

under conditioned sow. When a sow loses

condition, studies have shown that it has a negative effect on her subsequent

litter.

Many pork producers have acknowledged the importance of ad

lib feeding in lactation for a number of reasons. First and foremost, lactation puts huge caloric

demand on a sow as they are feeding larger litters. If we are not giving her access to full feed,

there is a chance she will lose condition, which will raise the likelihood of

that sow being culled exponentially as she turns from a productive sow to an

under conditioned sow. When a sow loses

condition, studies have shown that it has a negative effect on her subsequent

litter.

Next, if a pork producer is still hand feeding their sows,

they will run into a timing issue. A sow

is not going to stand up and eat when her litter is nursing and a producer

isn’t available at all hours of the day to wait until she’s ready to eat. In this particular scenario, how much intake

is that producer missing out on by only feeding a few times a day? On the flip

side, a producer may overcompensate by filling her feeder, but they run the

risk of wasting a lot of feed if she doesn’t consume it. This is where hand

feeding becomes a catch-22.

Lastly, how much is hand feeding costing your operation in

labor? Instead of time spent feeding an

even better question would be what could you or your employees be able to focus

on if you didn’t have to spend time hand feeding each sow multiple times a day?

In this video, Dr. Paul Armbrecht from Lake City Veterinary

Clinic talks about the benefits of ad lib feeding in lactation:

What makes the MealMeter system stand out from other ad lib feeders on the market?

The MealMeter system offers many unique features for feeding

today’s prolific sow. The PigEasy

lactation feeder has a one of a kind design that focuses her eating area, which

prevents feed build up and maximizes intake.

The PigEasy feeder also features an adjustable waterer. As this is her

ONLY source of water, not only will she completely clean her bowl up every time

she takes a drink, but she won’t be able to spray herself and her pigs in the

summertime. The feeder also has a weep hole near the bottom of each feeder so

excess water will not inhibit her feed intake even if a nipple should become

leaky.

The MealMeter itself has many attractive features, as it

needs NO adjustment, is easily removed and is made to last for years.

So let’s say...

... you are ready to take the plunge into an ad lib

feeder, but your current stainless steel feeders are still in great

condition.

While you won’t have the exclusive qualities of the PigEasy

Lactation Feeder, you can still have great success in ad lib feeding by

converting your existing bowl to the PigEasy set up.

This would include installing the adjustable watering

bracket and the MealMeter with Lactation boot in your current feeder. What’s

even better is we have made it (pig)Easy with templates and a short video

tutorial.

Watch Clint explain the most efficient way to convert your

bowl to the PigEasy system.

We are pork producers ourselves and understand the

difficulties a change like this entails. This is why we designed each product

to be installed many different ways on virtually any equipment.

If you have any questions, we would love to help! You can

reach us at 888-354-0112 or info@pigeasy.com.

Wednesday, April 22, 2015

Why I’m celebrating Earth Day

I think Earth Day in the past has left a bad taste in most farmers’

mouths because activists tend to use this day as a platform and a launch pad

for their attacks on innovation and progress in the Ag industry. I can’t blame

farmers in some ways. Animal and anti-GMO

activists are like that annoying mosquito who would rather be flattened with a

belly full of your blood, than to have the sense to get what they need, leave a

mark and move on to their next victim. See the latest on HSUS here, here and here.

So on a day when a farmer should truly be celebrated, they

get eaten alive by people who have zero experience cultivating the land or

raising livestock. That can leave

quite a lasting mark on someone who is typically very proud of their

livelihood.

|

| A beautiful evening during the 2014 planting season. |

Even so, today is a day that is supposed to celebrate all of

the resources we have the responsibility to care for, and I am proud to say

that my family is a part of an industry and a population that is achieving the

highest production in human history on less land all the while leaving a

smaller footprint on the environment, nurturing our resources for the next

generation and keeping our animals as comfortable and content as possible.

Very few professions are as in tune with and care as much

for our earth as farmers do. They wouldn’t

be in the business or successful at it if they didn’t. And with the vast majority of farms being

family operated, farmers want to pass their heritage and livelihood down to the

next generation in better shape than how they received it.

You can’t improve without innovation and progress. And sometime change like that can be scary. I’ve always been of the mindset that it’s

good to question as it means your mind is working and you are thinking for

yourself. The only thing I ask of you is

to look closely at your source of information, carefully discern what is news

and what is opinion and talk to an expert before making up your mind.

|

| I'm looking forward to Bobcat rides around our waterways again this summer! |

As for me and my family, it’s a treat to be a part of this

innovation and progress. We are thankful

for the blessings God has bestowed on us and we take seriously our

responsibility to leave the Earth in better shape for the next generation. Happy Earth Day, everyone!

Until next time,

Katie

Tuesday, April 14, 2015

PVC Glue on Stainless Steel Nuts & Bolts

|

| You can find PVC Glue at your local plumbing or hardware store. |

Tuesday's Trick of the Trade

You may have noticed our Tricks of the Trade so far have focused on stainless steel and how to overcome the issues that arise when using the material. While it’s not a producer’s goal to torment themselves and their help, the benefits of stainless steel certainly outweigh its headaches.

Today we're talking nuts and bolts... literally. We've all been in a situation where you are tightening or removing a stainless steel nut to/from a stainless steel bolt and even though they are both new, they seize together before you get anywhere, especially when using an impact wrench.

Here's a trick I’ve learned

years back to prevent stainless steel threaded nuts and bolts from seizing.

PVC Glue (Cement)

Prior to threading on a stainless steel nut, apply a small

amount of PVC glue to the first half of the threads with the brush.

Fasten the nut and go!

The glue helps lubricate, keeps the material cool and

reduces friction, which prevents the nut from seizing onto the stud/bolt.

The glue helps lubricate, keeps the material cool and

reduces friction, which prevents the nut from seizing onto the stud/bolt.

PVC Glue also works when you are trying to unfasten a

previous stainless steel nut and bolt.

Apply the glue to the rest of the threads before removal.

|

| Nut and bolt stayed cool to the touch and removed easily with the PVC Glue. |

Since Katie didn't believe me, I fastened and unfastened another bolt without the glue and the nut got hot and seized up on me before I could get it off. A brother's favorite victory is proving his sister wrong!

We have used this on many projects and this is our go to when

using stainless on stainless fasteners.

Have a great day,

- Ben

Tuesday, March 24, 2015

Pipe Thread Sealant vs. Teflon Tape

Tuesday's Trick of the Trade

Stainless steel is a great thing. It doesn’t rust and is

very sturdy; two material qualities that are important when working with hogs.

Where stainless can go wrong is during threading. Whenever we are at a show and mention a

nipple seizing up on a stainless steel fitting, every producer winces because

they themselves have been out in a G barn trying to unplug a nipple and nothing

short of cutting it off will fix it.

This is one of the reasons we developed the SnoutSpout nipple

bracket. It is made of glass filled polypropylene, a fiber infused plastic that

is extremely sturdy yet cuts like wood.

Now for the best part; the stainless steel nipples won’t seize up on

you!

The next question we typically get is whether or not to use

Teflon tape to seal the nipple to the bracket.

A plumber friend of mine recently cleared up a minor

misconception of threading.

Teflon Tape or Pipe Thread Sealant

The purpose of Teflon Tape is not to seal threads, rather it

is to stop the two fittings from seizing together. It may help with sealing, but that is not its

main purpose. If you are going to use a

stainless steel nipple with a stainless steel fitting, the best product to use

would be Teflon Tape alone or in combination with some pipe thread sealant.

Pipe Thread Sealant, though, is made to fill in the possible imperfections of threads of a male or female fitting to stop leakage around

them. This is what we suggest you use

with the SnoutSpout, as there’s no concern of the nipple seizing inside its female threads.

Pipe Thread Sealant, though, is made to fill in the possible imperfections of threads of a male or female fitting to stop leakage around

them. This is what we suggest you use

with the SnoutSpout, as there’s no concern of the nipple seizing inside its female threads.

Now we have a trick for applying Pipe Thread Sealant. Instead of applying directly

to the male threads of the nipple, we found it’s advantageous to apply the sealant around the first few thread grooves of the female fitting (SnoutSpout). As you

turn to insert the nipple, the sealant spreads around on the inside, instead

of being pushed to the outside, as it can be when applying directly to the male threaded nipple.

Ben likes to add that if you are in a jam in the barn, latex

hog marking chalk is a good substitute for pipe thread sealant.

What is a trick you use to seal your fittings?

- Dave

Friday, March 20, 2015

The Kitchen Table

Friday Feature:

The HUB of our house has always been the kitchen table. When outstretched to capacity, it is a 113

inch massive Farm Table.

It started as a place for candlelit dinners when we were first

married, a place to gather with friends for coffee, the little artist’s

workbench for different crafts, the laundry folding table, the homework station

for the young ones, the central place for prayer, the base for pictures of family

celebrations.

|

| A typical look at our "desk" set up. |

The kitchen table has always been my place to do bookwork

- a convenient way to multi-task – keep

an eye on the kids, watch the cookies in the oven and listen for the drier bell

to go off. Not to mention, you can

spread your work out easily. With the

start of PigEasy, the Kitchen Table has become a hot commodity.

You usually think of everyone having their “seat” at the

table ready to eat. Now Katie and I have

our “seat” at the table for business. It

is a good location for Dave to pop in to answer questions and Ben to pick up

order sheets. We have gathered around

the table to have product naming contests, have prepped some of our products

for production, and yes, we still eat at our table. Preparing for lunch

includes shoving the piles to the

other end.

It is with some excitement that we will be moving the

PigEasy office to a new location in town.

It is very exciting to have less clutter and less distraction – but I am

going to miss the activity around the kitchen table.

It is with some excitement that we will be moving the

PigEasy office to a new location in town.

It is very exciting to have less clutter and less distraction – but I am

going to miss the activity around the kitchen table.

We are used to having a “mobile office”. It may be a meeting in the shop,

brainstorming on the long drives, or the “feet up for 10” in the living

room. We now have an “official office” in our

future, but I have a feeling the HOME BASE of the KITCHEN TABLE will still be an active location for PigEasy

developments. And if any encouragement

is needed, the cookies fresh out of the oven always seem to work.

|

| Post-brunch product naming contest. |

- Karen

Wednesday, March 18, 2015

Improve your Gilts, Improve your Herd

Dave’s awakening occurred a few years ago at a regional boot

camp offered by his genetics company.

There, the presenter discussed the importance of gilt development. He said gilts are significant because the

size of their first litter can define their lifetime litter size, yet gilts

represent quite a challenge in many ways.

First, gilts need to be of ideal age, weight and condition

when bred to achieve optimal performance.

In order to accomplish this, feed intake must be maximized.

However, gilts experience a lot of changes prior to breeding

as they are moved from an isolation barn to a breeding barn. It often takes gilts a week to get back to

full feed after being moved, which is a week of limited intake days.

No producer wants to limit feed their gilts. But the conundrum turns into either the

producer wastes feed attempting to maximize feed intake or they set the boxes

back to save feed, which essentially limits the gilt until they are “used to

their new surroundings.”

After the presentation, Dave spent a lot of time

watching. He would observe gilts

entering the crate and would watch as they consumed (or didn’t consume) their

feed in the mornings and afternoons. In

the evenings, he would venture back over to the gestation barn to watch the

gilts and see if activity was any different.

Dave observed gilts aren’t stressed over the crate. They seemed to respond well to their

individual maternity pen. However, he

did notice the gilts would get up at various times ready to eat, but the feed

would be washed down the trough from the watering system or was no longer fresh

as they would prefer it.

Then it came to Dave; the isolation barns and breeding barns

have very different feeding systems.

Isolation barns or finishing barns have self-feeders, which allow young

gilts to eat small amounts through the day.

Individual maternity pens drop large amounts of feed into a trough one

to two times a day and the gilt is expected to consume it in a certain amount

of time before water washes it away or it becomes stale. As

Dave puts it, “We’re expecting our gilts to eat like sows.”

|

| MealMeter prototypes Dave tried out in his breed row. |

The wheels began to turn and prototypes were created. After coming up with a working design, Dave

put what is now called the MealMeter in front of his entire gilt row. His theory proved correct. Instead of taking days to get back to full

feed, gilts quickly consumed their ration when they could decide when they

wanted to eat. He was on to something.

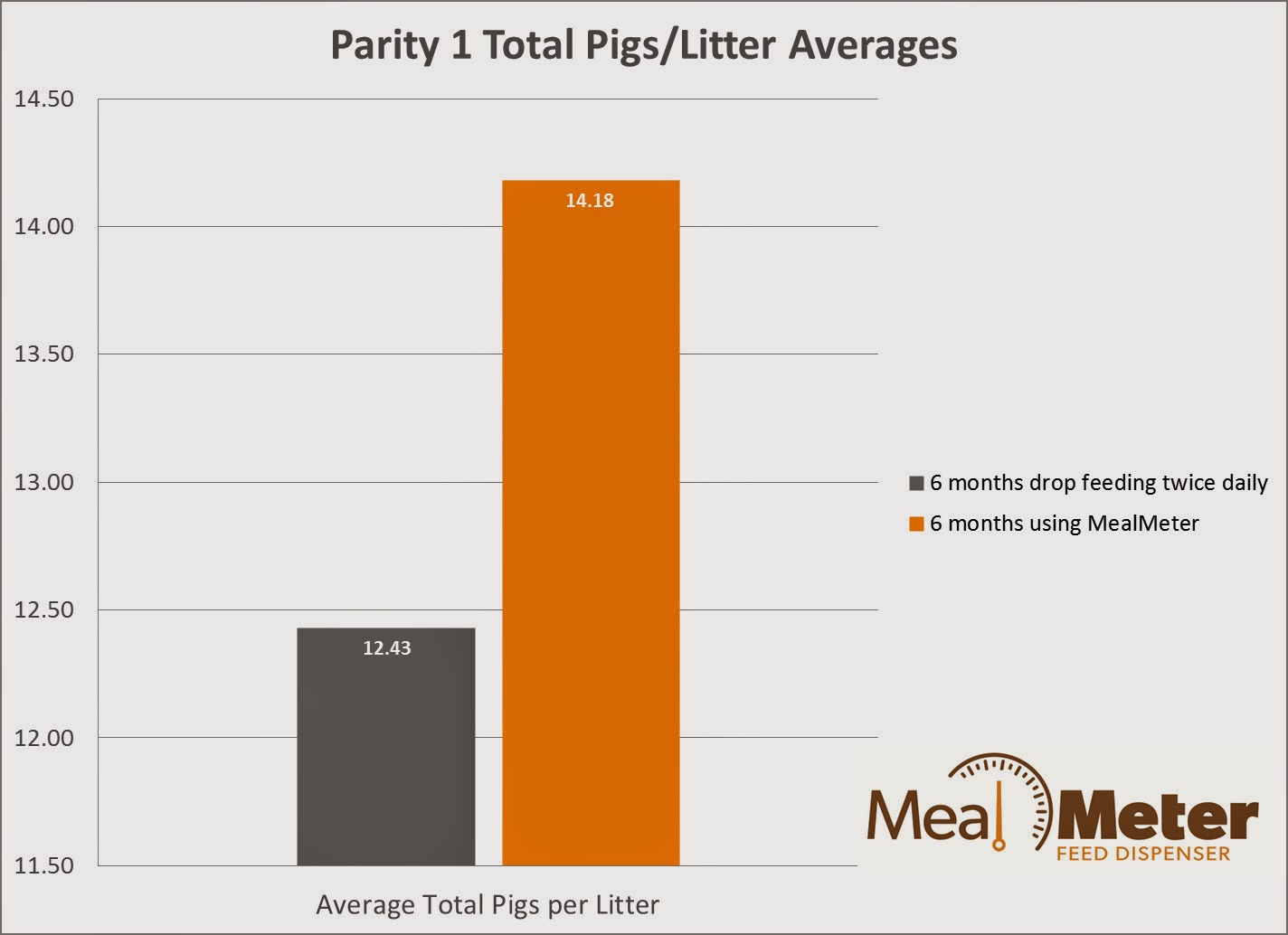

His production numbers told the same story. Before, he was in the bottom half of his

contemporary group for P1 production, even with a solid breeding team whose

conception rates are excellent. Six

months of using the MealMeter shot his numbers up to one of the top in P1 total

born. There were no other changes to

breeding and management.

|

| Dave's 6 month averages before and after installing the MealMeter. |

What is so exciting is P1 total born rate is just one benefit to consider. Aside

from obvious feed savings, think about what starting gilts off well can do for

the entire herd. For instance, Dave

significantly reduced his replacement rate because now that his gilts begin

well, they stay in the herd much longer.

Ron Ketchem and Mark Rix from Swine Management Services, LLC

wrote in the recent article ‘Does gilt performance dictate farm success’ that

not only does the farrowing rate of gilts correlate to the farrowing rate for

the whole farm, but also in the amount of repeats, total born, and wean to 1st

service intervals. “(Top farms) have figured out that gilts drive the farm now

and in the future. Most have invested in

good genetics, have gilt-developing facilities on the farm or close by and have

added labor to take care of the gilts from entry to breeding.”

Yes, gilts take more management and attention, but if you

start them off right, the benefits are far reaching.

Listen to Dave tell the story here:

Until next time,

Katie

Friday, March 13, 2015

Friday Feature: Clint, Aaron & Al

While I’m laying here on the couch recovering from recent

back surgery, I thought I’d write a little something about a few people

who are very important to PigEasy’s success.

Clint

|

| Clint is one of our most seasoned employees. |

With his ability and experience, Clint’s input with PigEasy

manufacturing and our products has been essential. He treats the business as his own and ensures

that each job is a job well done. In

addition to PigEasy and general farm work, Clint is our construction man and he

also keeps the shop and equipment organized and clean, which is not an easy

task when working with us Klockes!

Aaron

Aaron began working for PigEasy and Klocke Farms last August

and is quickly coming up to speed on the farm and PigEasy product line. He handles a lot of the manufacturing and

packaging for PigEasy. Aaron also helps on other various jobs with Klocke Farms. He is very eager to learn how and why we do

what we do to understand our process better.

We’re lucky to have someone with that much enthusiasm.

Al

Al began working with Klocke Farms part time a handful of

years ago. He helps with loading pigs and does the daily chores in the

finishing barn and helps with loading out. He also assists with various tasks

on the farm and is willing to step in and help when needed. His years of previous experience at the local

co-op have helped in many situations on the farm and we value his input.

I once heard that the key to success and happiness is to

surround yourself with the right people and I believe we have done just that.

Have a great weekend!

- Ben

Wednesday, March 11, 2015

What Role Does Nutritional Intake Play in Reproductive Performance?

Studies Show Avoiding Limited Intake Days (LID) Has Positive Impact

**** This article was included in a mailer last fall and confirms the importance of feed intake at key moments in a sow's reproductive cycle. That message is worth repeating!

Today’s research has brought advancements in genetics that have resulted in stronger animals able to produce and sustain larger litters. However, feed delivery practices have not kept pace with these genetics. Too often, sows and gilts are not getting the proper amount of nutrition when needed. These Low Intake Days (LID) negatively impact the overall condition of the animal and create operational losses through reductions in sow productivity, longevity and feed waste. On-site trials that have provided ad-lib feeding for newly introduced gilts and sows, pre breed and in lactation, revealed a significant link between the daily nutritional needs of the animals and what is lacking in current feeding practices. “A sow that produces 50 pigs in a lifetime versus 30 has a huge advantage for being able to have a reduced cost of each pig going out the door,” said Dr. Paul Armbrecht, a veterinarian from Lake City, Iowa with over 40-years swine experience. “Allowing these animals to determine when they feed has been proven to increase Parity 1 performance, reduce the replacement rate, bring gilts back to full feed on day one, get sows back into metabolic mode and recovering faster after farrowing; thus being able to produce more litters over their lifetime.”

Dave Klocke, owner/operator of Klocke Farms, Inc., and founder of PigEasy, LLC, believes the industry is shifting toward this long-term look at the productivity of the animal over their entire lifetime. Currently, pigs per sow per year is the measure for performance of the entire herd. The reality is, according to Klocke, that a better benchmark is pigs per sow per lifetime.

“Pigs per sow per year is not necessarily the most profitable, Klocke explained. “This individual animal is an investment, and because of LID, there are a lot of young females who do not get beyond P1 or P2 because they don’t consume enough feed at critical periods in their reproductive cycle. The sow doesn’t perform well. It is not her fault, it is a failure of the system to feed her properly by giving her all the feed she needs at the right time to achieve her genetic potential.”

Almost every producer, even the most experienced, knows that providing optimal feed intake is an issue, and until now, it has simply been treated as a matter of course. To address this, Klocke, through PigEasy, has designed and created the MealMeter feeding device. The MealMeter allows the animal to have access to feed on demand. He has put the MealMeter into his sow farm, and has seen a dramatic change since implementation.

“Our sow farm is now pushing 60 pigs per sow per lifetime,” Klocke said. “Industry average is probably under 40. Prior to utilizing the MealMeter, we achieved 50, and I was happy with that. Sixty pigs per sow per lifetime is not something we are driving for, it is just happening with a reduction in LIDs.”

For more information on the MealMeter feeding device and its accompanying products, visit http://www.pigeasy.com/pigeasy-products/mealmeter/.

Subscribe to:

Comments (Atom)