|

| World Pork Expo, Des Moines, IA |

The 2017 World Pork Expo is around the corner and we’re

putting the finishing touches on PigEasy products that will be featured in our

expanding booth (#V729). Even as we focus on promoting our tried and true

product line, Dave never stops developing new innovations.

The tough decision every May is “What do we put in our booth

this year?”

1. MealMeter feed dispenser -

|

| Stainless Steel MealMeter |

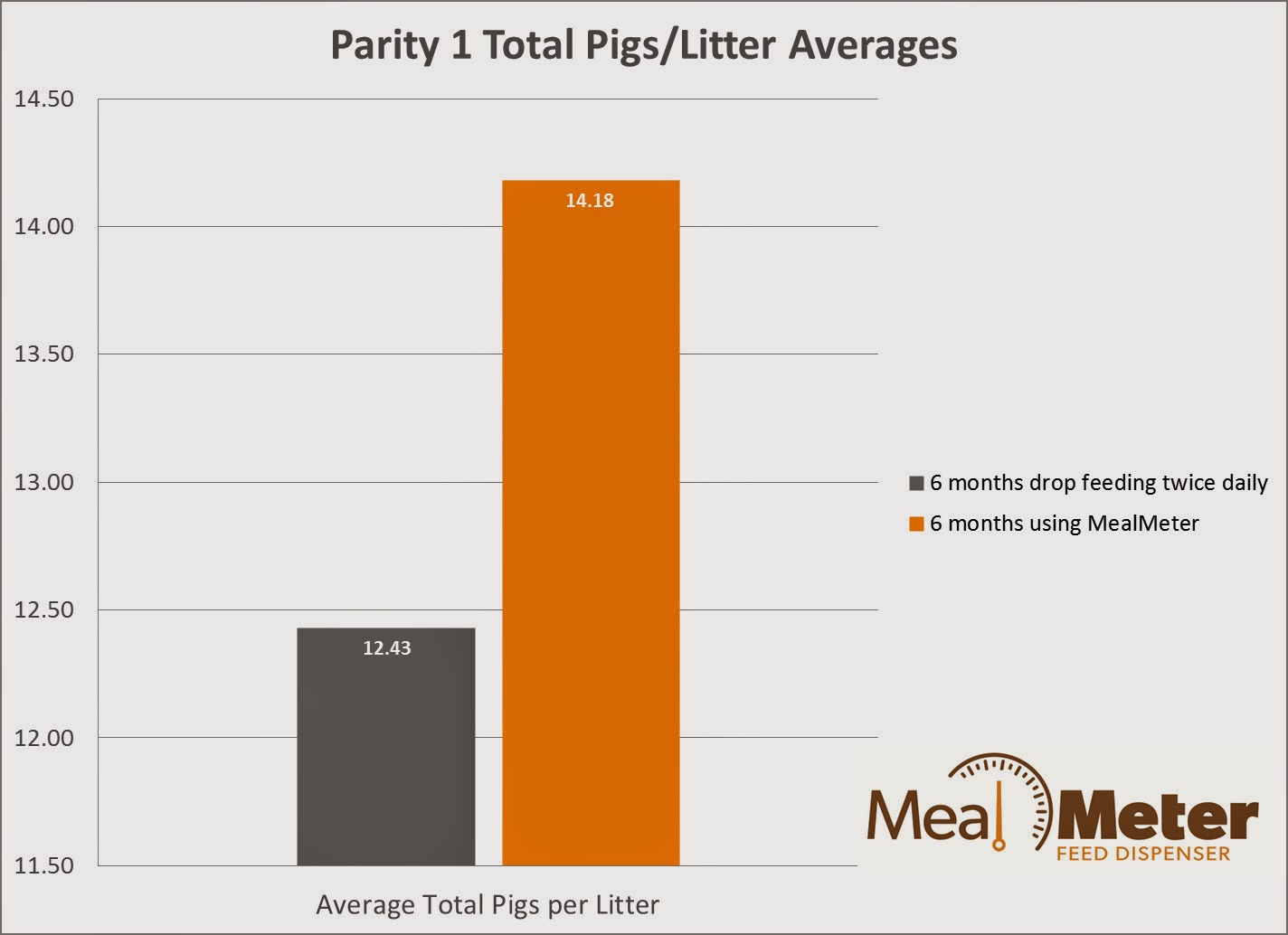

No question about it, we’ll have the MealMeter set up in a g-stall display. The MealMeter is what launched PigEasy and we are proud of how it boosts feed intake while preventing waste with incoming gilts, weaned sows and under conditioned sows.

2. PigEasy Sow Feeder -

The MealMeter will also be installed in the PigEasy Sow Feeder. The sow feeder’s one-of-a-kind design eliminates feed waste. (Yes, it really does!) By removing the corners, making this her only water source and using the MealMeter as the ad lib feed dispenser, you will get rid of the tedious task of cleaning out feeders.

|

| PigEasy Farrowing Crate |

3. PigEasy Farrowing Crate -

The PigEasy Sow Feeder will be displayed with the PigEasy

Farrowing Crate. Simple design with exclusive features, the PigEasy Farrowing

Crate is built with durability, ease of use, and sow comfort in mind. (Remember

the Flip Over feature?) Stop by our booth (#V729) to check out the one crate

that makes sow care a whole lot easier.

We’re launching a number of new products this year. Some

continue to focus on feeding because we know ourselves how feed is one of the

biggest expenses on the farm and is always an area of improvement at every

stage.

4. Breeder Bowl -

|

| PigEasy Breeder Bowl |

Speaking of PigEasy Sow Feeder, we’ve also wanted to allocate the success of the PigEasy Sow Feeder over to the breed row. To have the same feeding system in the breed row that’s also in farrowing makes the transition seamless and avoids any reproductive hiccups in the future. To mirror the inner workings of the Sow Feeder, we’ve developed the PigEasy Breeder Bowl. The Breeder Bowl benefits from the same bottom design as the Sow Feeder without interfering with her access to boar exposure during breeding. Like the Sow Feeder, the Breeder Bowl serves as both her feed and water source, which regulates over-dispensing and over-watering and is self-cleaning. If you’re wanting to take feed intake to the next level pre-breed, you need to check out the MealMeter with the Breeder Bowl set up.

5. PigEasy I.D. Cart

|

| PigEasy ID Cart |

Finally, we’ve branched out from feeders and tackled another major migraine on a sow farm; pig tagging. Certain programs require ear tagging all pigs farrowed on a sow farm and it becomes a time-consuming, fatigue-inducing chore. Ear tagging hundreds of pigs a day takes a huge toll on staff and can add stress to your hands and back. Klocke Farms employees were wearing down after starting a new program that required ear tagging, so Dave got to work. With help, he invented the PigEasy ID Cart. The PigEasy ID Cart is a foot operated double tagger that also serves as a holding cart for the litter. The PigEasy ID Cart also comes with a tagging sheet to organize your tags. I can’t even come close to being able to describe how cool this cart is. Check out this video to watch how quickly the team can tag pigs accurately and with much less effort. We’ll have one of these at the show as well, so you can test it out for yourself at the PigEasy Booth (#V729).

We’re looking forward to another wonderful year at the World

Pork Expo June 7-9 at the Iowa State Fairgrounds!

See you then!

Katie