Over the last few years, we’ve fielded a lot of questions on

the MealMeter feed dispenser. There are many I myself would

ask if I was in the customers’ shoes.

For those of you who are intrigued, but haven’t

caught up with us at a trade show or aren’t ready to make the call yet, here

are answers to the top five questions on the MealMeter feed dispenser.

1. What exactly is the MealMeter and how does it work?

|

| MealMeter feed dispenser |

The MealMeter is a feed dispensing device that is latched

(more on that later) in a drop feed tube in the breeding area of a sow farm. It

was developed to convert the feed tube into an ad-lib feeder.

Ad-lib feeding is popular in lactation because it is known

to optimize feed intake at a time when sows need to consume a lot of feed in

order to milk a healthy litter and not lose condition to be ready for her next

cycle. However, little was done before the MealMeter to improve feed intake for

pre-breed gilts, weaned sows and under conditioned sows in the breeding area

even though feed intake is very important at this time in her reproductive

cycle.

The MealMeter allows these sows the extra time needed to

consume their daily ration. Just like in the finishing barn, some sows are

“snackers” and some sows are “gorgers”. By giving her the freedom to choose

when and how much to eat, she’s able to maximize feed intake so she is in prime

condition to have another productive litter.

|

| MealMeter with Breeder Bowl |

The breeding area of the sow farm is where you can typically

expect a lot of wasted feed because it’s where we all try to push the limit of

feed consumption, but not in the way she needs it. Dropping a large amount of

feed to her one or two times a day is labor intensive because you’re going to

end up cleaning a lot of it out later when it becomes stale or rotten. Hand

feeding is labor intensive because staff is hand scooping their estimate of

what she is going to eat in each stall multiple times a day in order to drive

feed intake yet attempt to lower waste.

The MealMeter takes the human element out of feeding sows.

It saves on feed waste while at the same time pushes intake.

There are a couple different ways to set up the MealMeter in

the breed row. We’ll dig deeper into these two options later. In the meantime,

here’s a comparison between the two. Feel free to call (888) 354-0112 with any

questions.

|

| MealMeter in PigEasy Sow Feeder |

The MealMeter is also offered in farrowing where it is

inserted into an accompanying product, called the Lactation Boot, and installed

onto the sow feeder. To optimize feed intake, we suggest using the PigEasy Sow

Feeder, but the MealMeter and Lactation Boot can be retrofitted onto most

existing feeders, along with the lactation water bracket.

The key to feeding sows in lactation with the MealMeter

system is the water pipe in the feed bowl. The button nipple at the bottom of

the water pipe requires the sow to “self-regulate” the feed flow into the sow

feeder. Every time the sow goes in for a drink, she is cleaning up her eating

area so it is ready for her next meal.

2. Isn’t the sow just going to play with it?

This is probably the most popular question we’re asked about

the MealMeter. I believe it’s because of producers’ previous experiences with

ad-lib feeders where they see sows continue to fill up their bowl and never

fully clean it out.

Is the sow playing with the feed? In our experience, not

exactly.

Before I explain how the MealMeter is set up to not allow

the buildup of feed, I’m going to first explain the issue with ad-lib feeders

in general and feed build up.

We’ve observed many sows consume feed with different feeders

and we’ve come to the conclusion they aren’t playing. They’re layering.

With ad-lib feeders, sows are dispensing the feed, eating a

little bit, then heading back up for the fresh stuff without ever cleaning up

what they originally dispensed. That’s where you get this layering effect and a

bowl full of half eaten feed.

In breeding, the MealMeter’s set up options combat the

layering issue in two different ways.

The traditional set up has the MealMeter drop feed into a

dry trough. Sows are watered via the SnoutSpout nipple bracket installed on the

divider. The custom built feed tube has a viewing window toward the front

aisle, so as the staff walks the row throughout the day, they can set the boxes

to either push intake or hold back depending on the amount dispensed. Like Dad

says, “You can either take seconds managing feed at the feed box or on your

knees cleaning out the wasted feed that day.” With the MealMeter, feed is staying fresh in the tube until the sow is ready to eat. The traditional set up is where

we got our start with the MealMeter and led Klocke Farms to a 1.75 total born

increase with P1 sows.

The traditional set up has the MealMeter drop feed into a

dry trough. Sows are watered via the SnoutSpout nipple bracket installed on the

divider. The custom built feed tube has a viewing window toward the front

aisle, so as the staff walks the row throughout the day, they can set the boxes

to either push intake or hold back depending on the amount dispensed. Like Dad

says, “You can either take seconds managing feed at the feed box or on your

knees cleaning out the wasted feed that day.” With the MealMeter, feed is staying fresh in the tube until the sow is ready to eat. The traditional set up is where

we got our start with the MealMeter and led Klocke Farms to a 1.75 total born

increase with P1 sows.

We knew we could do more though. After coming to understand

the layering effect and setting up the sow feeder in farrowing to “self-regulate” with the

water pipe, we wanted to mirror that success in the breed row. So, we developed

the Breeder Bowl.

|

| MealMeter with Breeder Bowl |

The Breeder Bowl can be mounted on both straight front and sloped

front stalls. This eliminates the need for a trough. Existing troughs do not

pose a problem as the Breeder Bowl can be installed above the trough with

enough clearance to open the gate. The Breeder Bowl is small enough to not lose

any boar exposure and will not protrude into her stall space.

This new set up provides sows the freedom to choose when she

wants to consume her feed with little to no daily management.

3. How much feed does the sow dispense at a time?

|

| MealMeter Chambers (also part called the Elevator) |

I have to begin with a disclaimer that the answer depends on

your feed type and density. However, we’ve measured our own feed to get a

general estimate.

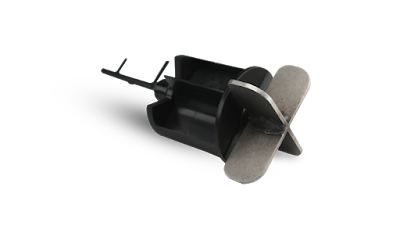

There are four moving chambers inside the MealMeter. As the

sow spins the MealMeter nose, the chambers are filled and the feed is dispensed

from the top opening of the MealMeter body.

Each of these chambers holds roughly 1/3 oz. Therefore, the sow will

dispense 1lb of feed with 12 complete spins.

Watch this video of the MealMeter in the breed row. You’ll

see the sow spins the MealMeter 2-4 times before actually eating. She eats for

a little bit, then heads back up for another 2-4 spins.

We’ve found the amount the the MealMeter drops to be a sweet

spot as it’s enough to satisfy her so she doesn’t get frustrated and not too

much that she inadvertently over-dispenses.

Another question we get asked that usually follows #3 is “How

much does a feed tube hold?” We custom manufacture 3 inch OD stainless steel

feed tubes for the MealMeter and can estimate that each foot of 3” OD tube

holds 1.65lbs.

4. How is the MealMeter removable?

The MealMeter has a latch on the top of the body and is

latched onto the stud that is installed at the top side near the opening of the

custom feed tube and the Lactation Boot.

To install or remove, stick a pliers handle or

screwdriver into the dispensing hole of the MealMeter body. This controls and

locks all the pieces together so you can successfully latch the MealMeter onto

the stud. Inserting it into the tube, turn the MealMeter toward the

latch. You’ll feel and hear a click to know it was successfully latched.

Removing is exactly the opposite. After sticking the pliers handle into the

MealMeter dispensing hole, you’ll turn opposite the way it was latched in until

you feel/hear a click and then pull out.

To install or remove, stick a pliers handle or

screwdriver into the dispensing hole of the MealMeter body. This controls and

locks all the pieces together so you can successfully latch the MealMeter onto

the stud. Inserting it into the tube, turn the MealMeter toward the

latch. You’ll feel and hear a click to know it was successfully latched.

Removing is exactly the opposite. After sticking the pliers handle into the

MealMeter dispensing hole, you’ll turn opposite the way it was latched in until

you feel/hear a click and then pull out. You can install the MealMeter on either side of the stud,

but we suggest you turn the MealMeter away from the sow to install. The sow

typically turns the MealMeter up (imagine a sow’s natural rooting movement) and

you want the sow to turn the MealMeter into the stud. If it’s installed the

opposite way, not to worry. The sow shouldn’t be able to get the MealMeter out

because she only has access to the MealMeter’s nose.

You can install the MealMeter on either side of the stud,

but we suggest you turn the MealMeter away from the sow to install. The sow

typically turns the MealMeter up (imagine a sow’s natural rooting movement) and

you want the sow to turn the MealMeter into the stud. If it’s installed the

opposite way, not to worry. The sow shouldn’t be able to get the MealMeter out

because she only has access to the MealMeter’s nose.

5. What if a MealMeter

piece breaks?

Sows tend to be a little hard on equipment, so we completely

understand why this is a top question. Taking that into consideration, we made

the MealMeter into four separate parts that are easily replaceable.

|

| MealMeter Parts |

There are two options to the the MealMeter nose, plastic or stainless steel. Most people choose the stainless steel option, but there are certain situations where plastic is most beneficial. Klocke Farms uses mostly plastic MealMeters. The nose is attached to a stainless steel

square shaft that holds the rest of the pieces. The chamber or elevator is assembled

inside the MealMeter body. The agitator or tail is installed on the back side

of that shaft. Everything is held together with a stainless steel roll pin.

Let’s pretend a rock comes through the feed line and busts

the MealMeter’s agitator. (I mean, you’ve only HEARD of things like that

happening, right? Us too. 😉)

You need a new agitator to keep the feed flowing, so you

give me a call, we send you out a replacement piece and a roll pin punch. You

simply punch out the roll pin, replace the agitator, put the roll pin back in

and you’re back in business.

The same goes for all of the other MealMeter parts. If you’re

having issues with a certain part of the MealMeter, there’s no need to replace

the entire thing. We can supply you with replacement parts and it takes little

effort to fix.

__

Our goal when developing the MealMeter was to make it easy

to use and manage and that’s not just because our name is PigEasy; it’s because

we’re pork producers too and understand what’s important to you.

If any of your top MealMeter questions weren’t answered,

send me an email (Katie@pigeasy.com) or

give me a call (888) 354-0112. I’ve got more information up my sleeve and would

be happy to help!

Until next time,

Katie